SOLUTIONS

TALIAN Best Solution

Enterprise Asset Management (EAM) IBM Maximo takes the management of your company’s critical assets and resources to a new level, all in a single platform. Maximo unifies comprehensive asset life cycle and maintenance management to reduce maintenance costs and increase production capacity, with no capital investment in production equipment.

WHY US

About TALIANTalian is an industrial solution provider that provides the solution to solve customer problems especially in the area of enterprise asset management. Customer satisfaction is our main focus, to understand what they need and assist them in every stage of delivering solution to resolve their problem and achieve the goals.

Read MoreThe highest-rated Enterprise Asset Management (EAM) solution in a decade

Optimize your enterprise assets by synergizing with CMMS

The biggest Maximo implementer in ASEAN

The most experienced Maximo implementer in Indonesia with a minimum satisfaction guarantee of 90%

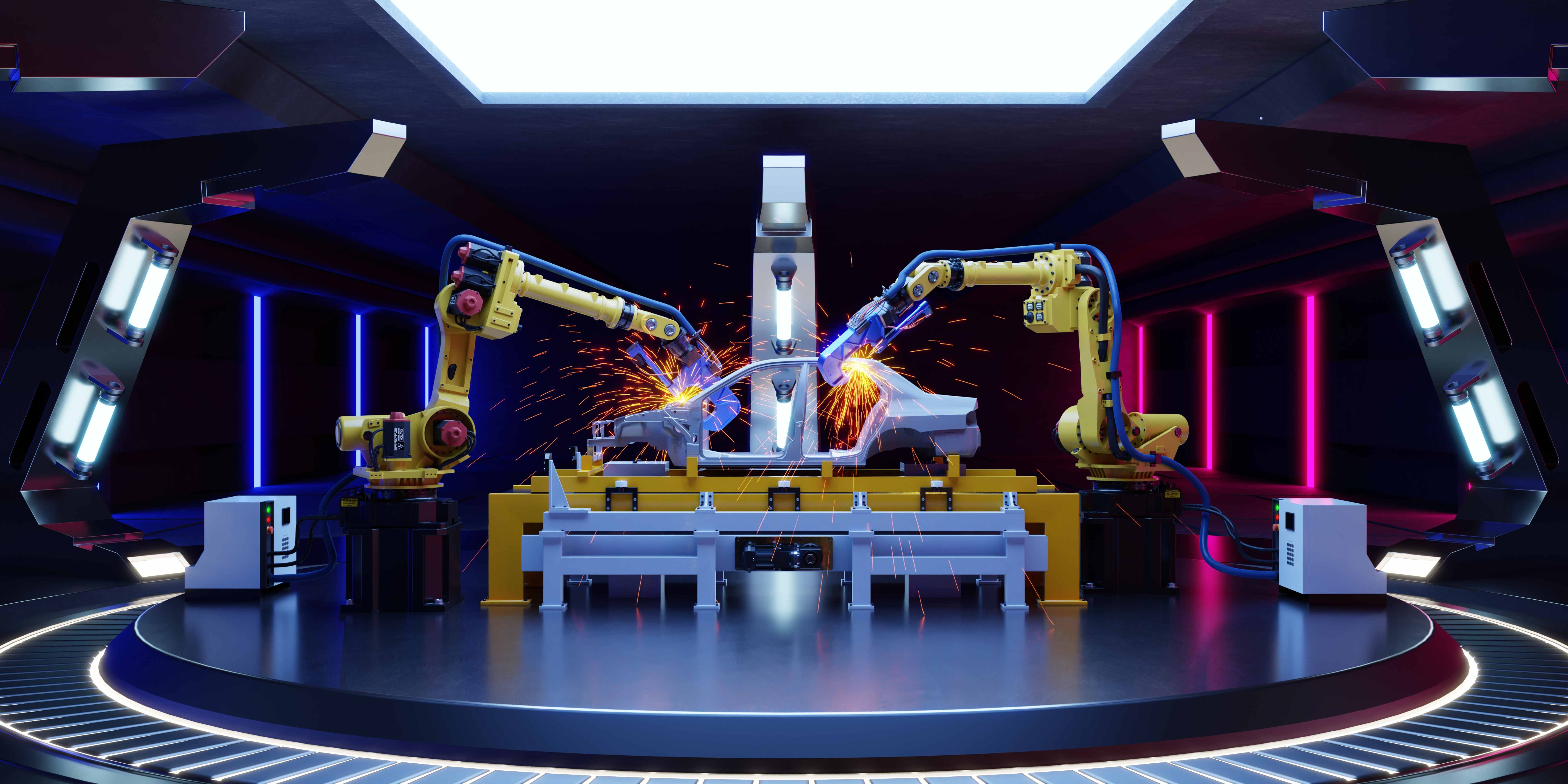

WHO NEED US

IndustriesCLIENTS & PARTNERS

Trusted by world-class company.png)

.png)

.png)

.png)

.png)

.png)